INJECTION MOLDING OF FACTORY

ONE - STOP PLASTIC Manufacturer

Chinese Factory , Not a trading company

- injection molding,Overmolding

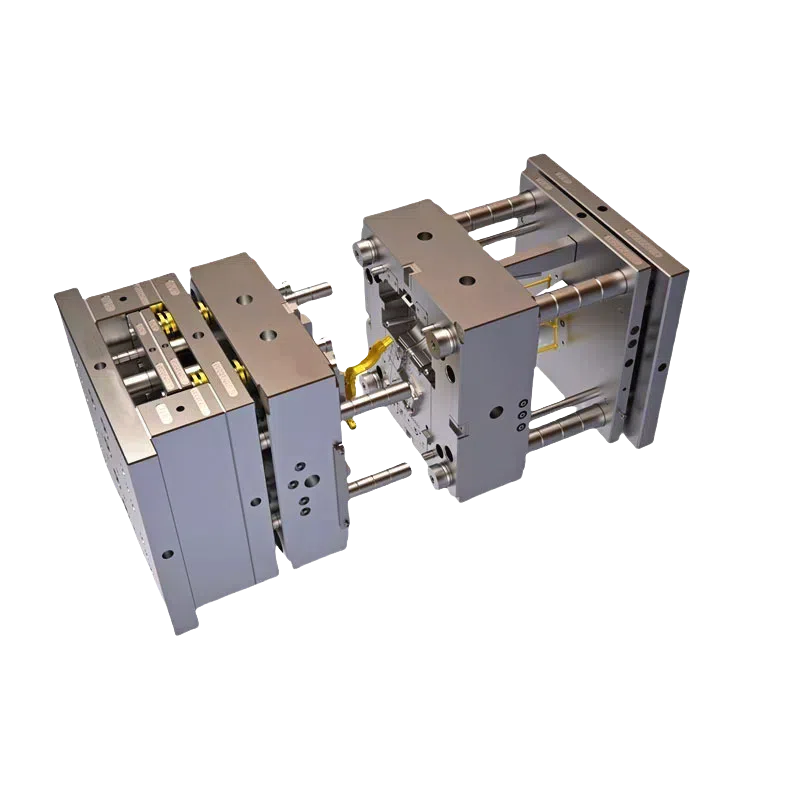

- Mold processing,Mold Design,Mold Machining,Mold Assembly,Mold Maintenance

- Surface Finishing:Spray Painting,Spray Coating,Rubber Paint,UV Coating,Electroplating,Hot Stamping

- Silk Screen Printing,Pad Printing,Laser Engraving,Hot Stamping

- Assembly product parts

PASS ISO9001 ISO14001 ISO13485 iATF16949

20 years of experience in mold processing and plasitc molding

- Free professional advi

- Free Mold Quote

- Free DFM Analysis

- Guaranteed after-sales service

- Guaranteed Delivery time service

- Guaranteed product quality

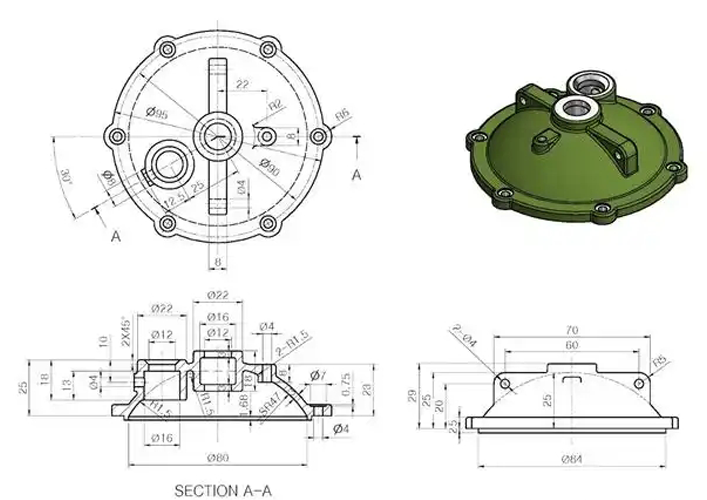

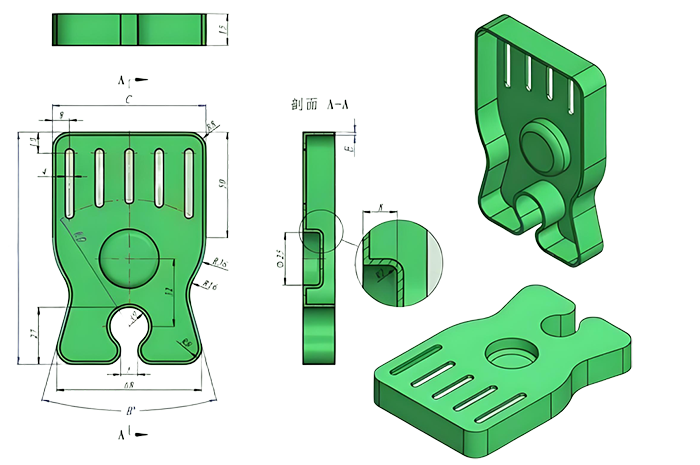

For a quote, please send 2D and 3D drawings

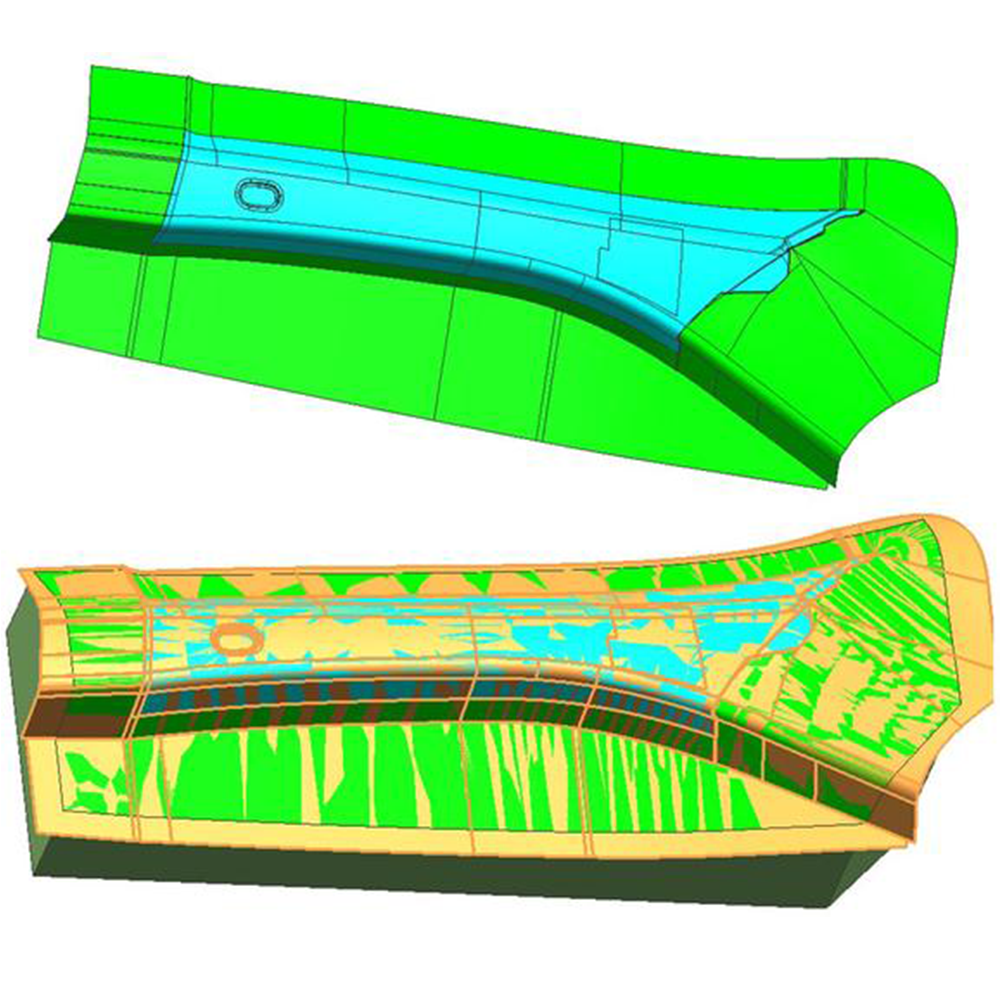

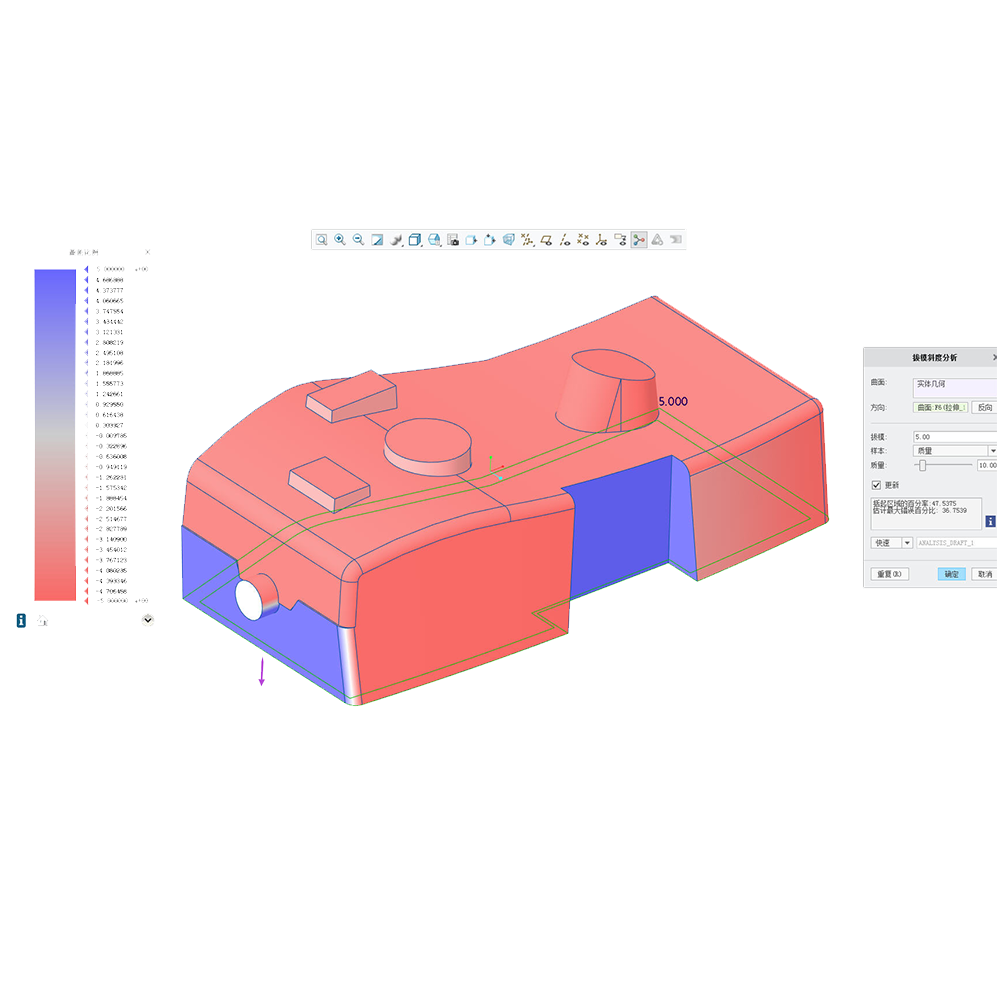

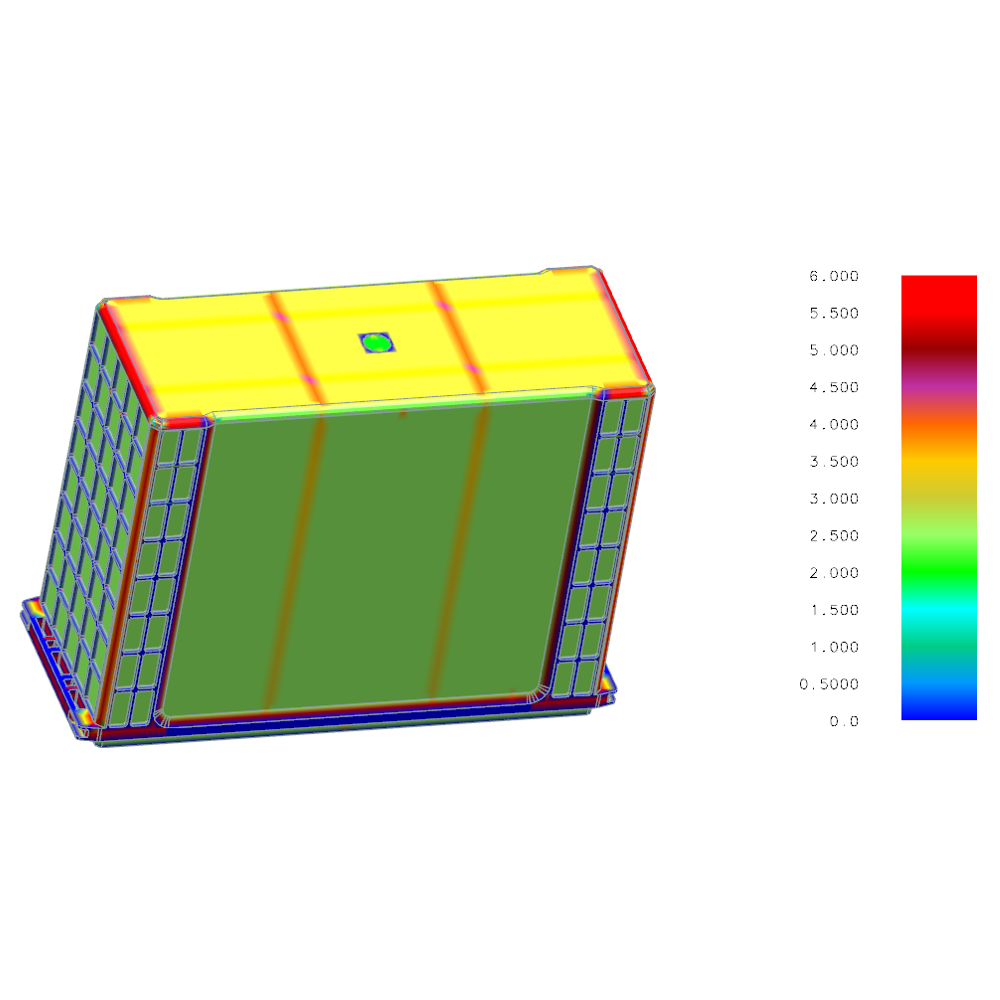

Feasibility analysis in the early stage

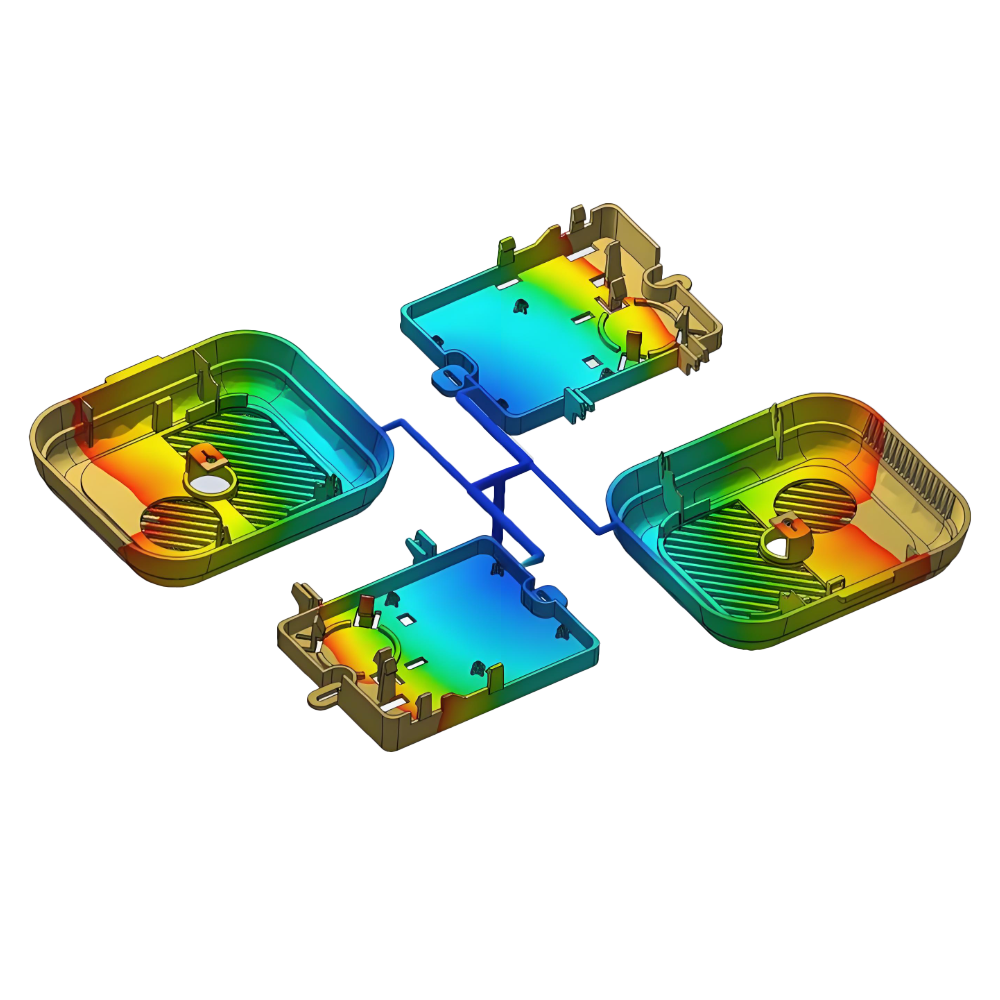

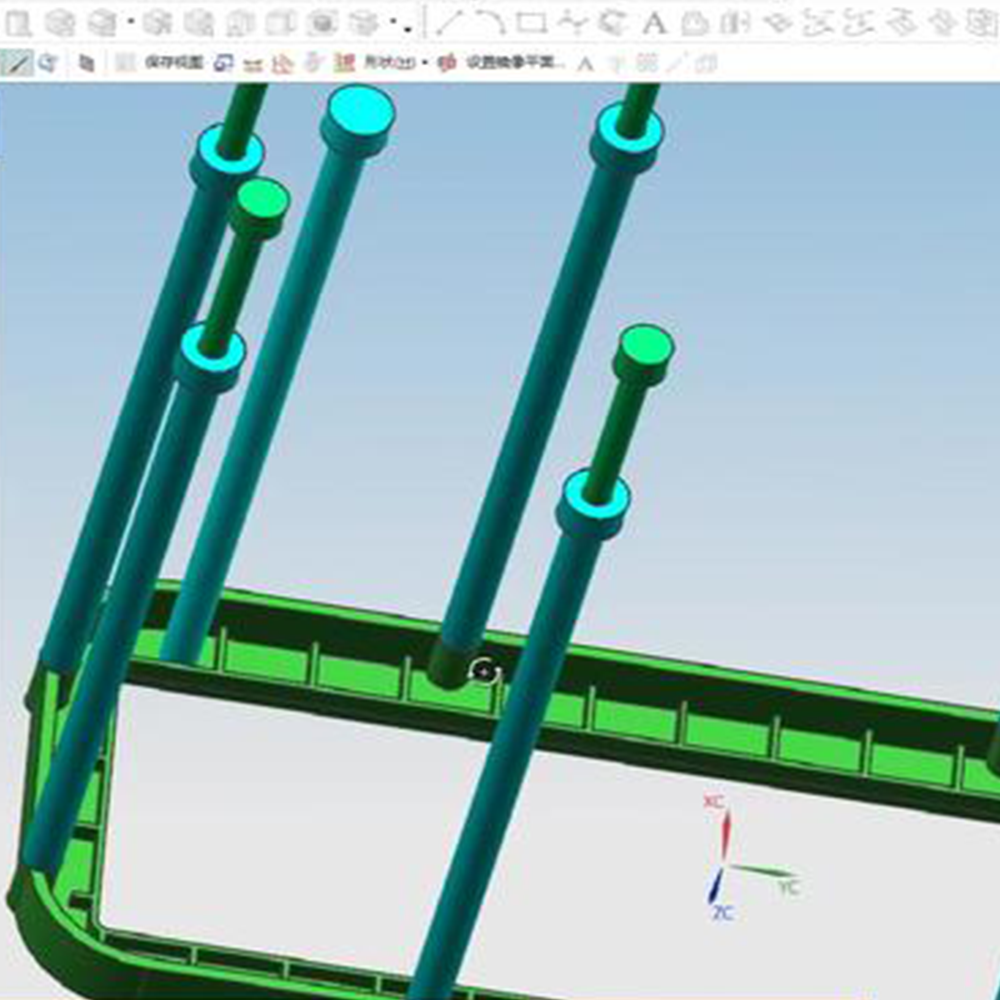

Mold flow analysis

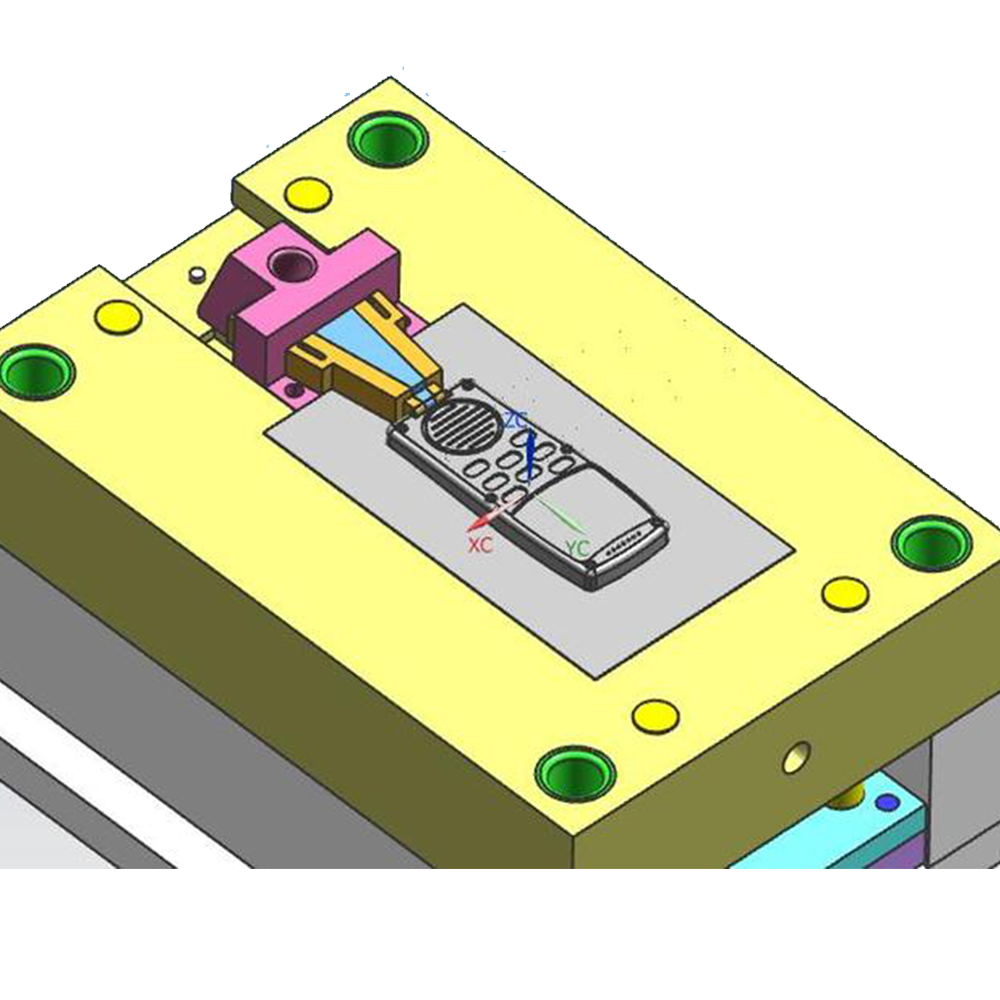

Mold product layout

MOLD Slider design

Plastic injection methods

MOLD Slider design

Product parting surface

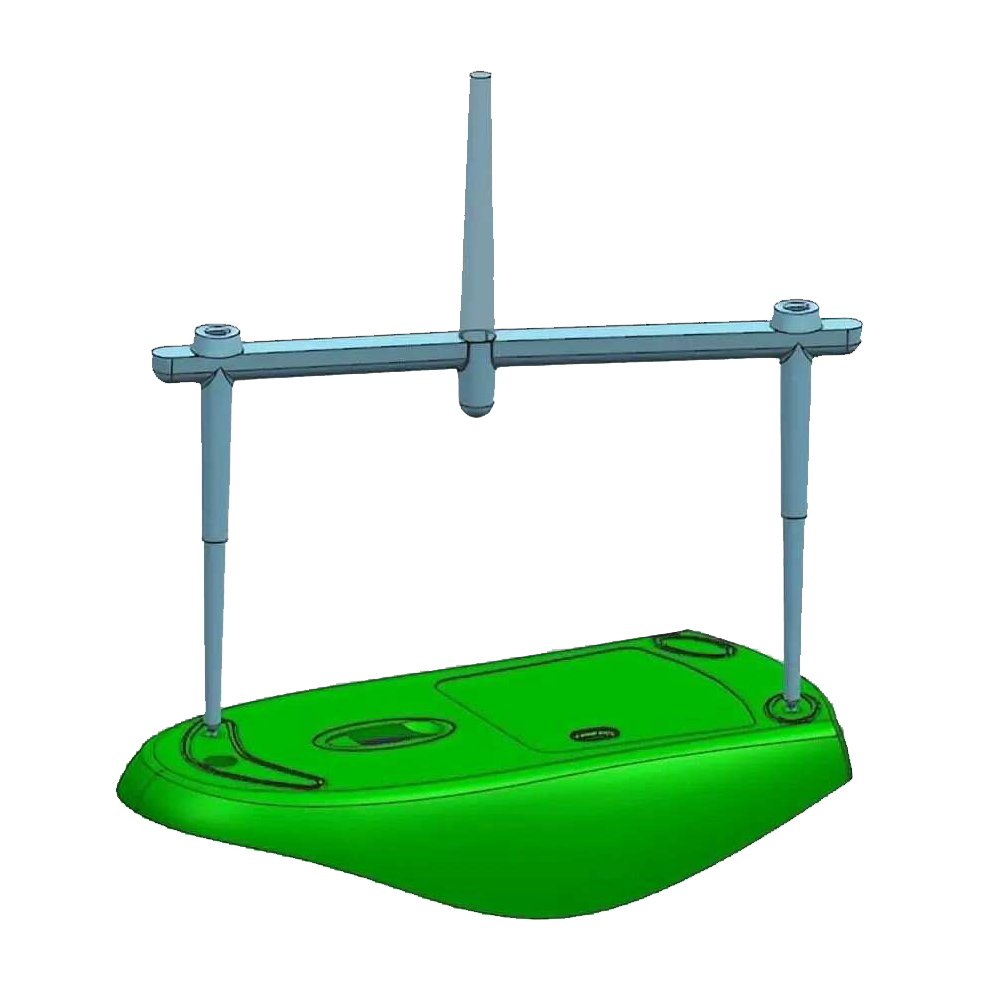

draft angle analysis

Thickness Part Analysis

Helping clients across industries create products

We can assist with developing your product, producing your product, launching your product, fulfilling orders, and providing customer support

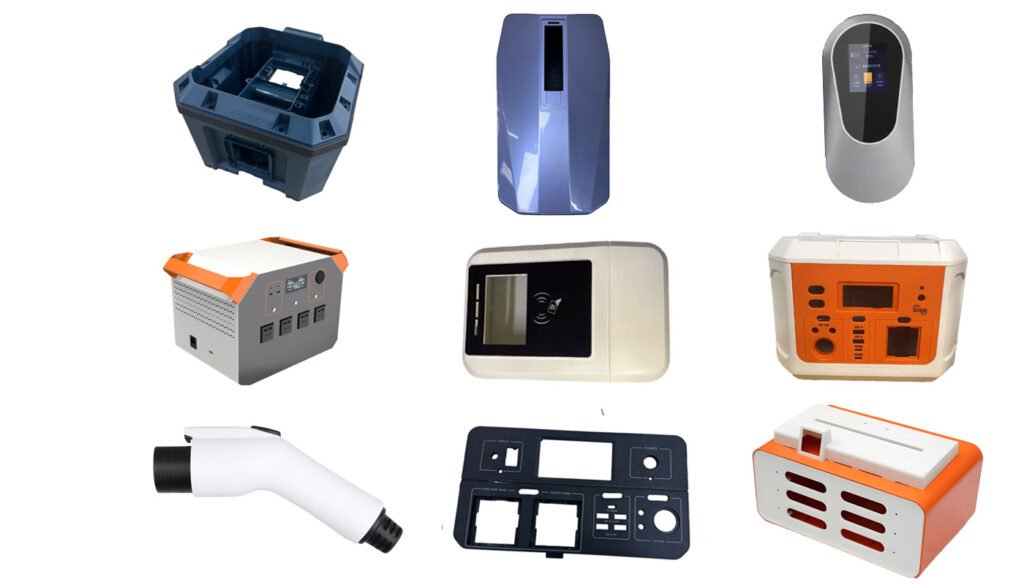

Consumer electronics

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

Medical product

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

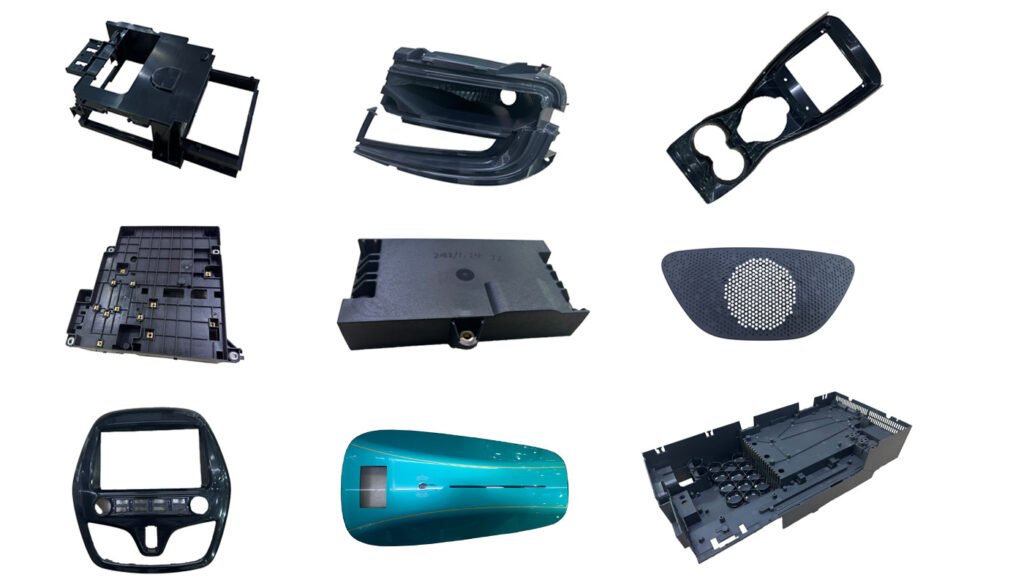

Auto parts

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

New nergy

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

household appliances

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

Proccesing Parts

- We provide complete plastic product solutions and a one-stop service from concept to mass production.

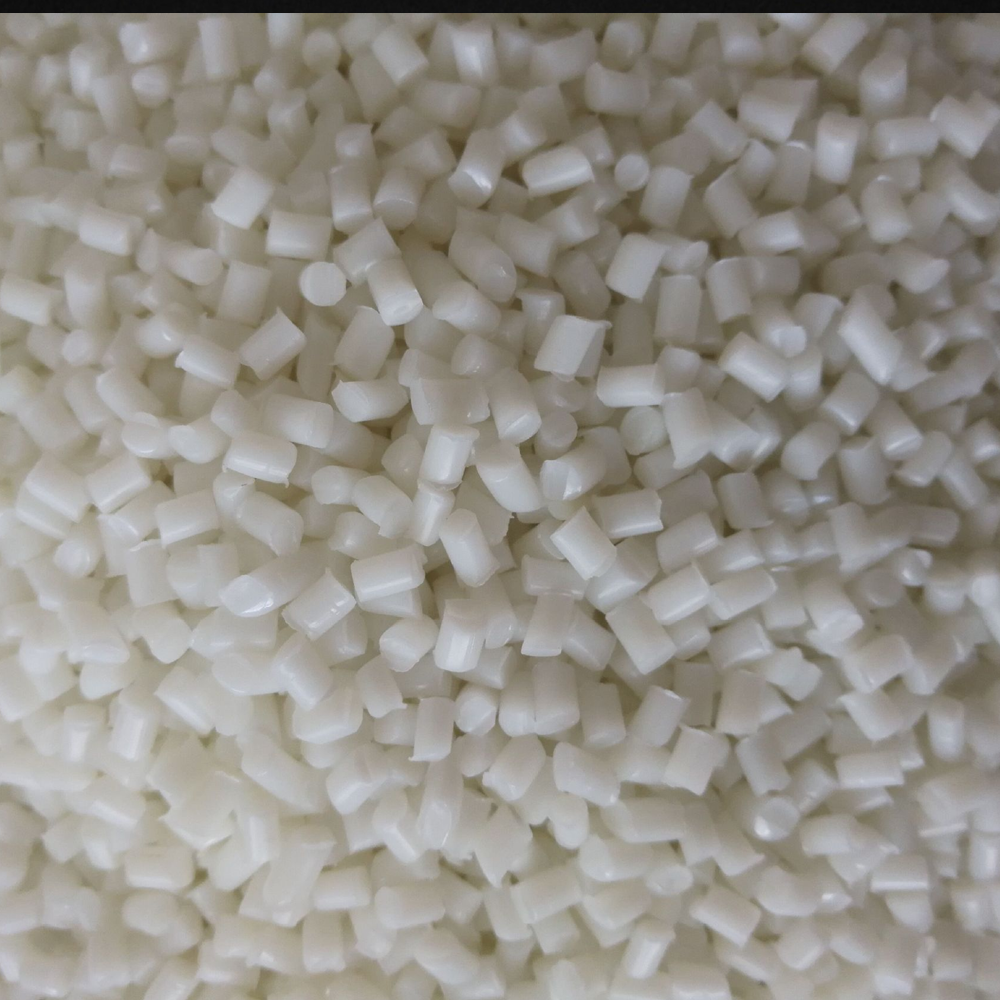

How choose Plastic Material ?

Choosing the right material is crucial for product quality, based on factors like fire/water resistance, corrosion resistance, impact resistance, transparency, electrical insulation, processability, and environmental standards.

PC

- High impact resistance

- High Transparency

- Heat resistance

- Electrical insulation

- Durability

ABS

- Impact resistance

- High strength

- Easy processing

- Chemical resistance

- Smooth finish

PP

- Chemical resistance

- Lightweight

- Fatigue resistance

- High melting point

- Electrical insulation

PA6/PA66 + GF 10-70%

- High strength

- Wear resistance

- Chemical resistance

- Good thermal stability

- Impact resistance

POM

- High strength

- Low friction

- Wear resistance

- Chemical resistance

- Dimensional stability

Other plastic material

- PS

- PE

- PMMA

- TPE

- TPU

Our mold making workshop

Choosing the right processing equipment is the first step in manufacturing quality products.We achieve excellent results by combining different equipment tailored to specific production needs.

CNC WORKSHOP

- CNC machines provide precise, automated machining for milling, turning, drilling, grinding, and engraving, ensuring high consistency and accuracy

Slow Wire Cutting Workshop

- Wire EDM (Electrical Discharge Machining) provides high-precision cutting of complex shapes by using a thin, electrically charged wire to erode material.

EDM WORKSHOP

- EDM (Electrical Discharge Machining) uses electrical sparks to erode material, enabling precise machining of hard and complex shapes.

Drilling Machine

- A drilling machine (drill press) precisely creates holes in various materials using a rotating cutting tool.

Mold Assembly

- Mold assembly involves fitting and aligning various mold components to ensure proper functionality and precision during the molding process.

Mold Maintenance

- Mold maintenance involves regular cleaning, lubrication, and inspection to ensure optimal performance and extend the mold's lifespan.

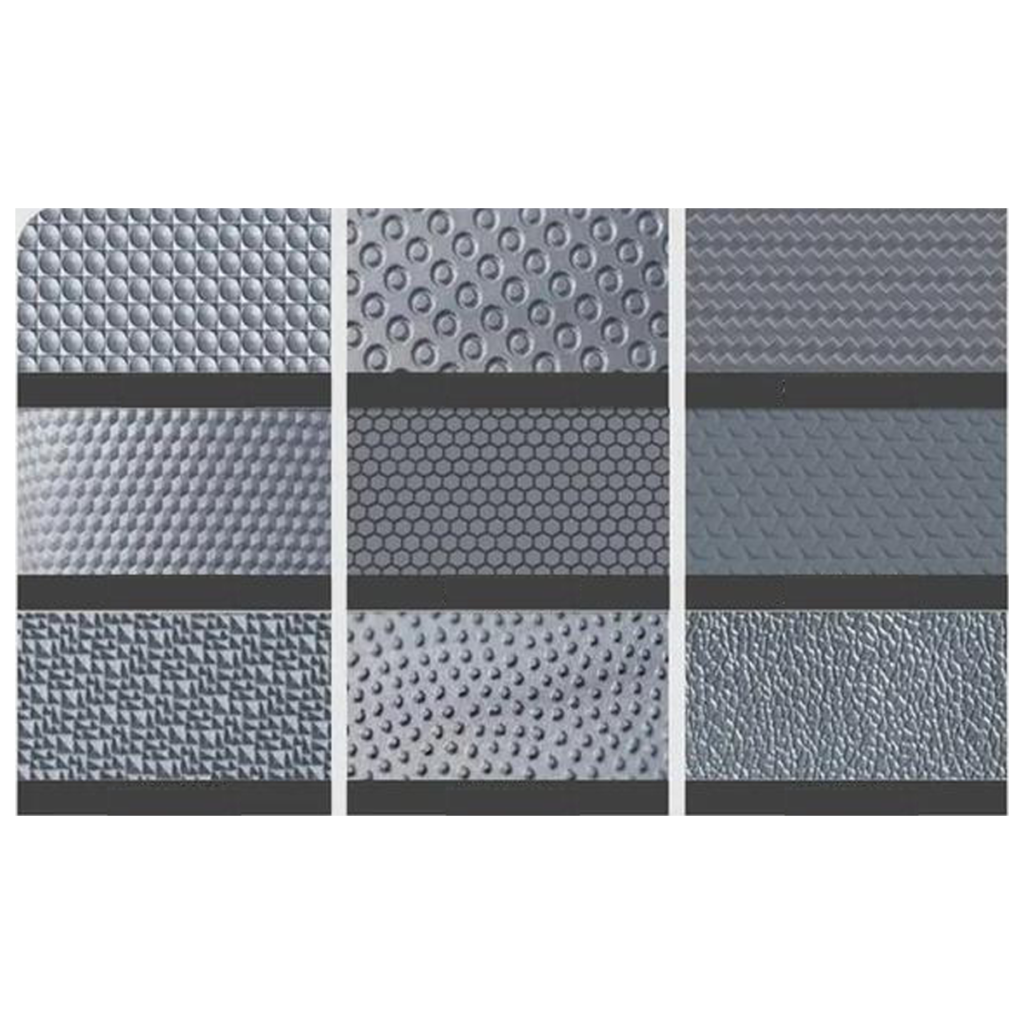

How choose mold surface processing

Mold surface treatment enhances durability, corrosion resistance, and precision by applying processes like polishing, coating, and heat treatment.

VDI SURFACE

- VDI standards for mold surface treatment outline methods for improving surface quality, wear resistance, and functionality, ensuring optimal mold performance and longevity.

SPI SURFACE

- The SPI (Society of the Plastics Industry) standards for mold surface finish define the required texture and smoothness levels to ensure consistent part quality and efficient mold performance.

ETCHING SURFACE

- Mold etching creates a textured surface on molds, enhancing part aesthetics, grip, and functionality by using chemical or electrical processes to form patterns.

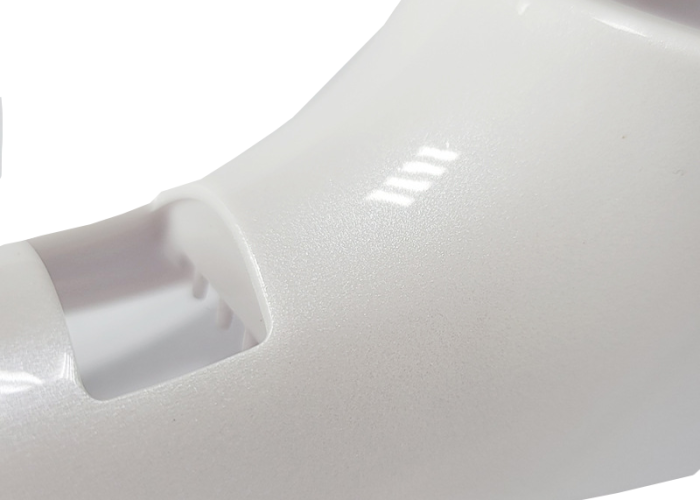

INJECTION MOLDING WORKSHOP

We company has 100 injection molding machines, offering a range from 120 tons to 1500 tons, with sizes ranging from a maximum of 1500*1500 mm to a minimum of 100 mm by 100 mm.

injection molding of two workshop

-

120 - 250 ton machine

Maximum mold size : 500*500*500(mm)

Maximum Injection volume :500(g)

injection mold of one workshop

-

250 - 650 ton machine

Maximum mold size : 830*830*830(mm)

Maximum injection volume : 2576(g)

injection molding of three workshop

-

650 - 1500 ton machine

Maximum mold size : 1500*1500*1500(mm)

Maximum injection volume : 7800(g)

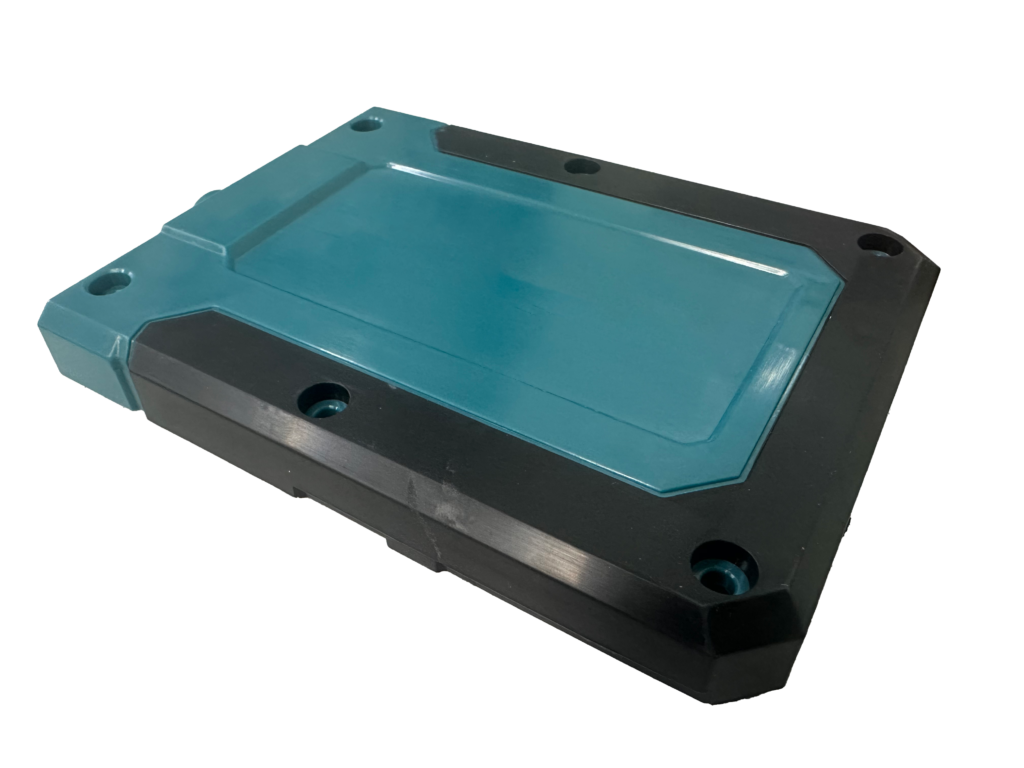

How choose plastic molding Processes

The significance of overmolding is to enhance the functionality, durability, and aesthetic appeal of a product by combining multiple materials in a single manufacturing process.

Two-Shot Overmolding

- Involves molding a second layer of plastic over an already molded part to enhance its properties or functionality.

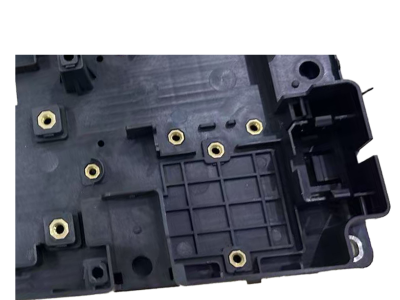

Metal Insert Molding

- Combines metal components with plastic by molding plastic around a metal insert, improving strength and durability.

Hot Melt Insertion

- Involves injecting plastic around a copper nut to create a strong, corrosion-resistant bond between the metal and plastic.

Multi-Shot Molding

- Uses multiple injection cycles to add different materials or colors to a single part in one process, achieving complex designs.

TESTING LABORATORY

Final testing, painting, and assembly ensure the product meets quality standards, functionality, and aesthetics before it reaches the customer.

TESTING ROOM

- The plastic testing process evaluates the material's performance, durability, and quality to ensure it meets the required standards for its intended application.

3D TESTING MACHINE

- The metal testing process assesses the material's strength, durability to ensure it meets industry standards and performs reliably in its application.

ASSEMBLY

- Product assembly combines individual components into a complete, functional unit, ensuring proper fit and operation.

Spray Coating Workshop

- Spray painting enhances the product's appearance, provides a protective coating, and improves resistance to wear and corrosion.

Surface Finishing Processes

The purpose of secondary processing and surface treatment is to improve the material’s appearance, enhance durability, increase resistance to wear and corrosion, and ensure the product meets functional and aesthetic requirements.

Spray Coating

Spray coating involves applying a thin, even layer of paint or protective material to a surface, improving appearance, durability, and resistance to environmental factors.

Spray Painting

Spray painting is a process of applying a coating of paint to a surface using a spray gun, ensuring a smooth, even finish and enhanced protection against wear and corrosion.

UV

UV coating is a process that uses ultraviolet light to cure or dry a coating, providing a durable, glossy finish with enhanced resistance to scratches, chemicals, and UV damage.

Electroplating

Electroplating is a process that uses electric current to deposit a metal coating onto a surface, improving its appearance, corrosion resistance, and durability.

Silk Screen Printing / Pad Printing

Silk screening (screen printing) is a process where ink is pressed through a mesh screen onto a surface to create precise, detailed designs or text.

Laser carving

Laser engraving is a process that uses a focused laser beam to etch precise patterns, text, or designs onto a surface, offering high accuracy and durability.

Hot Stamping

Hot stamping is a process that uses heat and pressure to transfer metallic foil onto a surface, creating a shiny, decorative finish.

Plastic FAQ

Plastic shrinkage

Cracking

Warpage

Air Bubbles

Burn Marks

Plastic air mark

SUCCESS - RAIN

Our plastic injection molding advantages

One - stop plastic sulotion

Fast manufacturing delivery

EXW FOB CIF DDP FCA

T/T L/C D/P Advance Payment / T/T

Non-Disclosure Agreement

Free pre-sales and after-sales consultation

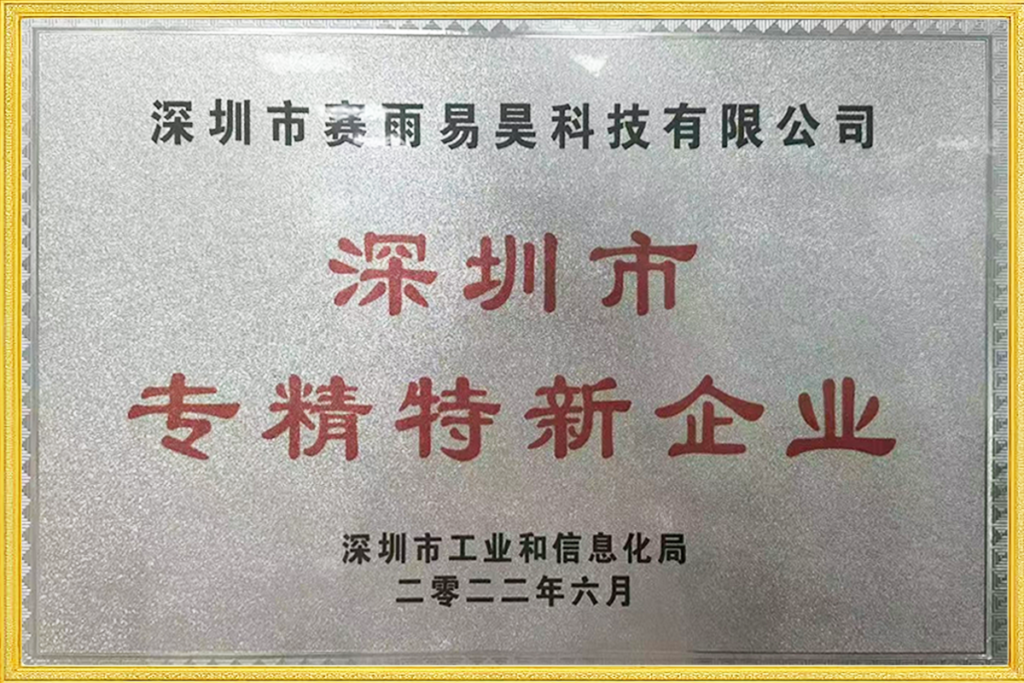

ISO 9001

ISO 14001

ISO 13485

IATF 16949

National High-tech Enterprise

National professional skills enterprise

What Our Customers Say About Us