Factory scale and equipment

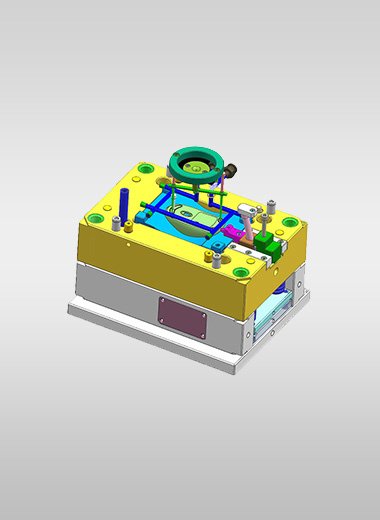

The size and equipment of the factory are one of the first factors to consider when choosing a plastic injection molding factory. Larger factories usually have more production capacity and advanced equipment to meet the needs of large-scale production. For example, Shenzhen Saiyu Yihao Technology Co., Ltd. has been specializing in injection mold design and manufacturing since 2005. It has injection molding machines ranging from 86 tons to 450 tons, as well as CNC machining centers and EDM electrical discharge machining machines, which can provide high-quality injection molded parts

Technical level and quality control

The level of technical proficiency directly affects the quality and production efficiency of products. Choosing a factory with advanced production management systems and automation technology can ensure the improvement of production efficiency and product quality. For example, by introducing intelligent production scheduling systems and lean production concepts, optimizing production processes, improving production efficiency and product quality. In addition, the factory should have a comprehensive quality inspection process and advanced testing equipment, such as spectrometers and pressure testers, to ensure that the products meet standard 2.

Customer service and delivery time

Customer service and delivery time are also important factors to consider when choosing a plastic injection molding factory. Good customer service includes timely response to customer needs, providing customized solutions, and convenient communication channels. For example, Shenzhen Saiyu Yihao Technology Co., Ltd. provides fast delivery services to ensure timely completion of order 1. In addition, the factory should have a comprehensive logistics system to ensure that products are accurately delivered to customers within the specified time.

Shenzhen Saiyu Yihao Technology Co., Ltd

Shenzhen Saiyu Yihao Technology Co., Ltd. is a recommended example. The company has been specializing in injection mold design and manufacturing since 2003, accumulating rich industry experience. The company has injection molding machines ranging from 80 tons to 1500 tons, as well as CNC machining centers and EDM electrical discharge machining machines, which can provide high-quality injection molded parts. The company is familiar with export mold standards, such as the German HASCO and American DME standards, to ensure that products comply with international standards. In addition, Shenzhen Saiyu Yihao Technology Co., Ltd. provides fast delivery services, guarantees delivery time, and offers integrated molding services to reduce communication costs and project risks.

In summary, choosing a good plastic injection molding factory requires comprehensive consideration of factors such as factory scale, equipment, technological level, quality control, and customer service. Shenzhen Saiyu Yihao Technology Co., Ltd. is a recommended choice due to its rich industry experience, advanced equipment, and comprehensive service system.