plastic mold manufacuturing is a crucial part of modern manufacutring,providing precise tools for the production of various plastic products.

The design and manufacutring of molds involve multiple complex steps.each of which has a significant impact on the quality of the final product.

This article will introduce the basic process flow of plastic mold manufacturing.

The basic process of plastic mold manufacutring

The manufacturing process of plastic molds usually includes four major steps:design,processing,assembly,and trial molding

Each step requires extremely high precision and technical level to ensure that the mold can be produced effectively and stably.

Mold design

The design of molds is the first step in plastic mold manufacturing.Designers analyze the customer’s requirements and the specific characteristics of the product(such as size, shape, material, etc.) to select the appropriate mold type (such as single cavity mold, double cavity mold, multi cavity mold, etc.).The design process needs to consider factors such as the molding method,demolding method, and injection pressure of the product. At this stage, CAD (computer-aided design) and CAE (computer-aided engineering) software are often used for simulation and optimization design.

Mold processing

Mold processing is the core process of plastic mold manufacturing, usually including milling, grinding, turning, electrical discharge machining and other processes. Mold steel is usually subjected to strict heat treatment to improve its hardness and wear resistance. In this process, precision machining equipment and technology are crucial to ensure that the size and shape of the mold meet the design requirements.

Mold assembly

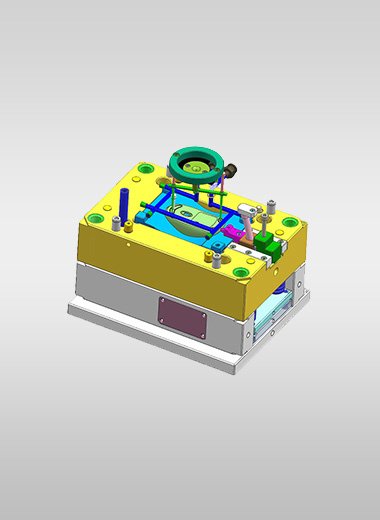

After the mold processing is completed, it enters the assembly stage. This stage involves assembling the various components of the mold (such as the mold core, mold sleeve, ejector pin, etc.) into a complete mold system. During the assembly process, precise adjustments are required to ensure that all parts of the mold can fit smoothly without getting stuck or experiencing excessive friction.

Trial molding and adjustment

After the mold assembly is completed, a trial mold is required. The purpose of mold testing is to check whether the mold can work properly during the actual injection molding process, and whether there are any defects or problems. During the trial molding process, if any problems are found, such as poor molding, difficult demolding, or mold damage, engineers need to adjust the mold design or processing technology based on feedback until the mold can stably produce qualified products.

Summary

The manufacturing process of plastic molds involves multiple links, and the accuracy and quality of each link directly affect the performance and cost of the final product. By continuously optimizing design, precision machining, strict assembly, and repeated mold testing, the efficient production and long-term use of plastic molds can be ensured. This series of technological processes is the foundation of modern plastic product production, supporting the manufacturing needs of various industries worldwide.