In the plastic manufacturing industry

plastic molds are one of the key production tools. Recently, the plastic mold industry is leading the trend of innovation, using the latest technology applications to help enterprises improve production efficiency and product quality. The following are the latest technological trends and innovative developments in the plastic mold industry:

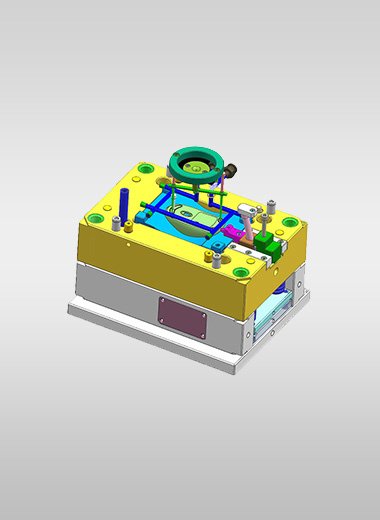

Digital design and manufacturing:

With the continuous advancement of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, digital design and manufacturing have become an important trend in the plastic mold industry. By using advanced 3D modeling software and simulation tools, designers can create complex mold structures more accurately and conduct simulation testing to optimize the design. Digital manufacturing technologies such as CNC machine tools and laser cutting have improved the manufacturing accuracy and production efficiency of molds.

Rapid prototyping technology

Rapid prototyping technologies such as 3D printing and rapid cutting have brought revolutionary changes to the plastic mold industry. 3D printing technology can quickly manufacture complex shaped mold components by stacking materials layer by layer, reducing the time and cost in traditional manufacturing processes. Rapid cutting technology utilizes high-speed cutting tools and advanced tool materials to achieve efficient processing of mold parts, improving production efficiency and quality.

Intelligent and automated production

With the rapid development of artificial intelligence and automation technology, the plastic mold industry is also actively applying intelligent and automated production systems. The intelligent mold manufacturing process can achieve data collection and analysis through sensors and real-time monitoring systems, improving the controllability and reliability of the production process. The application of automated production lines and robot systems can achieve automatic loading and unloading of molds, workpiece inspection, and quality control, improving production efficiency and consistency.

Innovation in Materials and Coatings

The application of new materials and surface coatings has provided new breakthroughs in the performance and lifespan of plastic molds. For example, high-strength and wear-resistant engineering plastic materials can increase the durability and damage resistance of molds. Advanced surface coating technologies such as diamond based thin film coatings (DLC) and nano coatings can reduce friction and wear, and extend the service life of molds.

Networking and remote monitoring:

The plastic mold industry has realized networking and remote monitoring by using the Internet and Internet of Things technology. Through remote monitoring systems, mold manufacturers can monitor the production process and equipment status in real time, identify and solve potential problems in a timely manner, and improve production efficiency and reliability. In addition, networking provides a more convenient platform for collaboration and communication among mold designers, manufacturers, and customers, accelerating the speed of product development and delivery.

The plastic mold industry is constantly moving towards a new era of digitization, intelligence, and automation driven by the latest technology. The application of these innovative technologies not only improves the production efficiency and product quality of plastic molds, but also provides strong support for enterprises to maintain a competitive advantage in the global market.