Mold processing: the art of precision manufacturing

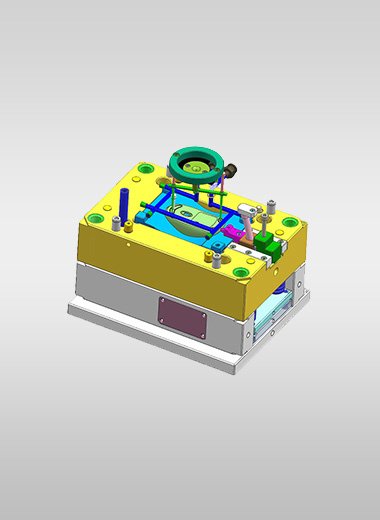

Mold processing is an indispensable part of modern manufacturing industry, which not only concerns the quality and production efficiency of products, but also serves as an important support for technological innovation and industrial upgrading. Mold processing covers the entire process from design, manufacturing to maintenance, and each link requires extremely high precision and craftsmanship. Through precision milling, slow wire cutting, and electrical discharge machining techniques, mold processing can achieve precise machining of complex three-dimensional surfaces and narrow and deep cavities, ensuring the perfect formation of products.

Mold processing technology: a leap from tradition to modernity

Traditional mold processing relies on manual operation and simple mechanical tools, while modern mold processing utilizes advanced CNC technology and automation equipment. The advancement of milling processing has made it possible to process complex three-dimensional surface parts, and the application of high-speed milling and five axis machining technology has significantly improved production efficiency and machining accuracy. Slow wire cutting and electrical discharge machining further expand the application scope of mold processing, which can handle various high difficulty and precision mold manufacturing needs.

The importance of molds in industrial production

Molds play a crucial role in industrial production. From car dashboards to electronic connectors, almost all industrial products cannot be formed without molds. The quality of the mold directly affects the appearance, function, and durability of the product. Therefore, mold processing not only requires high-precision manufacturing technology, but also strict quality control and continuous technological innovation. Through continuous optimization of processing technology and material selection, the mold processing industry is developing towards higher efficiency and precision.

The future trend of mold processing: intelligence and greenness

With the advancement of technology, mold processing is gradually developing towards intelligence and green direction. The introduction of intelligent production lines makes mold processing more efficient and flexible, and can quickly respond to changes in market demand. At the same time, the application of green manufacturing concepts has made mold processing more environmentally friendly and sustainable in material selection and production processes. In the future, mold processing will pay more attention to technological innovation and ecological friendliness, promoting the manufacturing industry to move towards a higher level.

Case Study on Mold Processing: A Comprehensive Analysis from Design to Application

Taking the mold processing of automobile dashboard as an example, from the design stage, designers need to fully consider the plasticity of materials and the stress distribution during the molding process to ensure the quality of the final product. In the manufacturing stage, complex three-dimensional surfaces and small holes can be accurately machined through precision milling and slow wire cutting techniques. Electric discharge machining is used to process complex shapes and deep cavity parts, ensuring that every detail meets the design requirements. Finally, after strict quality inspection and optimization processing, the car dashboard was perfectly formed, meeting the requirements of high precision and high performance.